My New Years Resolution #1 was to make a million dollars.

My plan calls for me to churn out a spiral dresser in two man-days:

One day to stack it, and one day to shape it. The rest, I’ll farm out.

On paper, this makes a lot of sense, and I made a quick twisted stack out of 2×6’s which went together just about that fast.

Next up is a pipecleaner. Something that forces me to go through all the motions, solve all the problems, and produce a perfect piece. Before I start taking orders for 100 of these, I need to make the first one first. So that’s what I’ve been doing. Single mindedly.

I decided to make a left-handed mirror image of my old dresser and I brought home 110 linear feet of dimensioned 8/4 cherry boards.

I have never worked with dimensioned hardwood.

When I used to build furniture, I always started with rough lumber. I’d lug it, plane it, rip it, and work around every knot, twist, warp and bend in the pile. It’s a ton of work.

And then I started working with reclaimed wood. Which is even worse.

But dimensioned hardwood is perfectly straight and flat and square. It will make spiral dressers a snap!

And for awhile, everything was going great. I cut my wood into 44 pieces, built the drawer boxes, and watched the glue dry. So far so good. Then, my friend Josh pointed out that my crosscut saw was ‘just a little off.’ So now I had 13 slightly crooked drawer boxes on my hands. And where the glue’s gotta go, the surfaces weren’t very flat. Sigh.

The surfaces have to be flat.

I did the best I could. I modified a drum sander I’ve had for years. I upped its capacity from 4″ to 9″, and then ran the drawer boxes through it till the edges were flat.

In all, I sanded an inch off the height of the dresser.

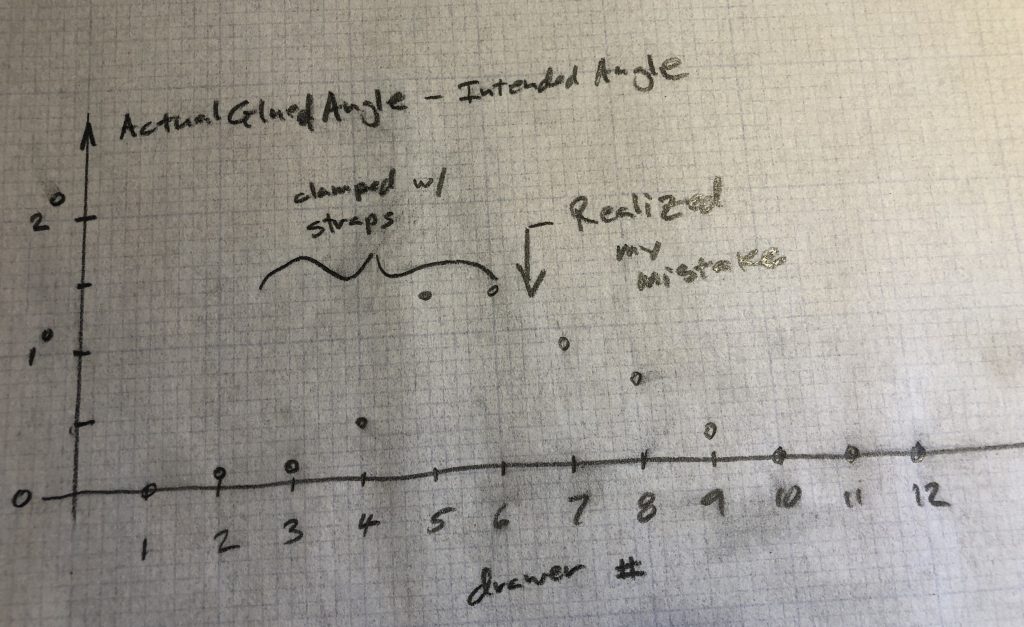

When it came time to glue the stack of boxes together, I ran into problems right away and, while looking for a fix, I managed to make things worse by using straps to clamp 4 of the drawers.

Then the trouble started.

Once in awhile, the gantry motors wouldn’t track. And every time I thought I’d tracked it down and fixed it, it didn’t help. I gave up and replaced the motors and the drives, and it’s worked better than ever, ever since. Sometimes, giving up is the best thing you can do.

But the real problem was the rotary table, which bogged down under the weight of the assembled dresser. I did not see this one coming. This is a big honking piece of iron that comes with a free grunt every time you move it, and they say it’s only rated for a 15 pound load. WTF? Well it certainly doesn’t like 150 pounds!

I had to re-engineer the whole front end of the mill so the table can torque the load without supporting it. This set me back over a week. And thank God for plan C, because plan B didn’t work either.

There were lots of problems. Lots of mistakes. Lots of learning.

But in the end, the design was robust enough, and the mill was accurate enough, and I was lucky enough, and it came out perfect.

New Years Resolution #2 was to learn to tap dance.