In retrospect, it was probably my own fault.

I was cutting too big a hole, too fast. The tool strained, the metal screamed, the shop shook, and the mill ground to a halt.

In one fluid motion, I hit the switch and backed away. The angry grunting stopped, and I got a whiff of ozone.

Usually when this happens (!) something simple is wrong, and it’s an easy fix. But this time, the head bearing was seized. And my morning was ruined.

It didn’t help that I didn’t have a pin spanner wrench, which you need to open up the head.

It didn’t help that it was Sunday, either. Or that the only open hardware store didn’t have a pin spanner wrench.

And it didn’t help that the next day was the 4th of July, and everything was going to be closed.

So by the 5th, I had full blown metal shop withdrawal syndrome, and by the time Mary got out of bed, I’d already done a motorcycle tour of every auto parts store in town. None of them were any help at all. God damn it.

Well God helps those who help them selves, I guess, because I made two primitive wrenches and used them to reset the main bearing in the head of the mill.

And then I finished that too-big hole that broke the mill in the first place.

Nice and easy.

Last winter, I got to thinking …

Wouldn’t it be cool, I thought, if I had one big towel bar that wrapped around the whole bathroom? A towel bar that doubles as a grab bar as it detours through the shower! It’s a crazy thought, I admit, but the more I thought about it, the more I liked it. And when I planned the new bathroom, I planned it around snazzy, modern towel bars, front and center, left and right, wall to wall. It looked really good on paper!

Well today, I finally got around to installing it, and it was one of those things you have to see in 3D, in person, to appreciate. It was butt ugly. It was an affront. It did not look like I’d hoped it would look. At all.

Mary agreed. Yuck.

We brainstormed it, and I took out the ugliest parts, and it went from crude to refined. From ugly to elegant. It’s a fine line, and it was a close call.

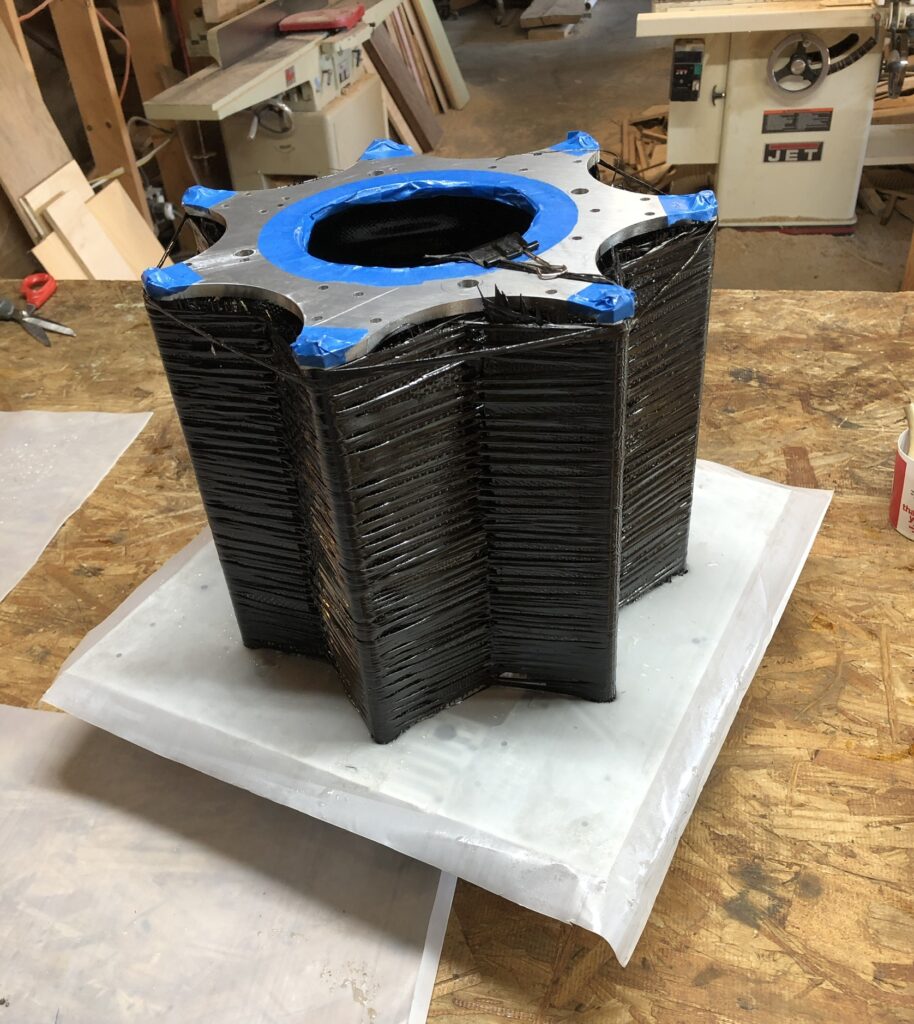

For the last week or two, I’ve been working on the parts and procedures for a carbon fiber linkage for B3PR. In principle, it’s simple: 2 plates, 7 rods, 14 screws and 25″ of CF tube, all wrapped in about half a mile of carbon fiber ‘tow.’ In reality, it’s a million little details, and they all have to be right. It’s not exactly the Webb telescope, but it’s close. When it came time to glue it up, I was sweating. Wouldn’t it be just like me to make a dumb mistake at the last minute and fuck the whole thing up?

Well, today was the day: Everything seemed ready, and I took a deep breath and I glued it up, and it went well. And while the adrenaline subsided, I watched the glue dry, making sure it didn’t fall apart. Afterwards, I made another half a dozen special trips into the cellar, just to watch the glue dry. It’s looking good so far.

Remember the soapstone counter we ordered 6-8 weeks ago? It’s ready. Woo Hoo!

I built a berth for it in the bed of the truck, and we headed for Perkinsville to pick it up.

Now, before I get too far here, let me bring you up to date. Remember the Template I traced from the sink and mailed to them? They got it just fine, thanks.

Then I mocked up the faucet we’d bought with the sink we had, in the cabinet I’d built, using the Template I’d sent them, and it was obvious, immediately, that the faucet was an inch too far back. Something had to give, but I had too many balls in the air to figure it out right away, so I told them “just don’t drill the faucet hole. I’ll do it myself.”

“No problem,” they said. “We can do it.”

Problem solved! One less thing to worry about for 6-8 weeks.

Fast forward 6-8 weeks. We drove down to Perkinsville to pick up our countertop, and found that they’d drilled the hole anyway. Shit.

Finger pointing aside, I had a choice: I could suffer more delays and trouble, or find another faucet, so I took my slab, faucet hole and all, and went home. I was pissed.

I set about looking for a bathroom faucet with a longer-than-average spout, to compensate for the hole placement. There were none at the box stores, and online, my choices went from about 3000 to about 20 — mostly uber-modern designs priced for sheiks.

We found a nice one with a 6 1/8″ spout. Some would say I’m compensating.

The countertop slab is a heavy sonofabitch, and about as delicate as a big piece of rock can be. I was super careful not to scratch it, not to bump it, not to mess it up in any way. To lift it onto the counter, I rigged up my electric lift with straps and 2x4s, so I could raise and lower it with the touch of a thumb, and it got 90% of the way up with no trouble at all.

Then it fell.

It cracked the pendant. It smashed a drawer.

It tore a gash in the wall and dented the floor.

It broke into a thousand pieces, and it made a hellova thud.

I can play it back, a frame at a time, in my mind. I know exactly what I did wrong, and I won’t be doing that again!

Strictly by coincidence, a week ago, I attended an auction and won a very nice tile saw. And now that I have lots of soapstone fragments to cut, maybe I’ll think of something to make with it.