thu sep 1

I worked on the motorcycle all morning. I started out with 6 thermocouples, placed everywhere in the exhaust pipes, and watched the bike warm up. I took temperature readings at different rpms. Cylinder #2’s temperature is erratic and low, and I don’t know why, but I backed out its fuel pilot screw 1/2 turn anyway. I burnt my hand doing it, and it didn’t seem to make much of a difference anyway.

Just because it doesn’t run good doesn’t mean it won’t pass inspection, though, so I took it down to S&S and he flunked it because the brake pads are shot.

It was not a good day for the motorcycle.

The second floor heating system is looking good next door. I’ve got pipe stubs in each room, and I got started on the downstairs. All these years, I’ve been holding on to a drawer full of used copper fittings, thinking how I’d find a use for them – someday. And today was the day! I tellya, for all the work it takes to clean away the lumps of cold solder before you can re-use them, they’re just not worth the trouble.

sat sep 3

I fit and welded the last, smallest, hardest, most prominent facets onto the fan hood, and I’m here to tell you: “I got it right.” I feel like I’ve come a long way as a welder in the last 2 years.

Drink to that, willya !?!

At least something went right, because the motorcycle sure isn’t.

Even though I synced the vacuum, it still doesn’t run right, and there’s got to be a reason for it. Here are a couple of new data points:

When I’m idling, closing off the air pilot screw has no effect. This tells me that “the basic vacuum is so bad that it’s still really bad after a slight improvement.” So, thinking back, I recall that when I synced it the other day, they were all kinda in the red zone on the gauge, compared to mid-range when I synced in the spring.

So this morning, I opened up the carbs again and hooked up the gauge, and when I tried to tweak the sync, the knob bottomed out. Not just one of them: all of them. So whatever is messing up the vacuum is messing it up in every cylinder. (compression is also low again, too.)

So here’s my latest theory: The valves have seated themselves since I ground them 2000 miles ago, so the clearances are back down to zero and they’re not closing, and the blowback ruins the vacuum and the idle jets don’t draw, and it dies.

So I took the bike downstairs, took off the air box, the carburetor, and the valve cover (and spilled gas on the basement floor). Tomorrow, I’m going to check & change the valve clearances.

Ever since I bought it at an auction, Mary has wanted Nothing To Do with the power washer. Today, she decided the back deck needed to be cleaned and re-coated, and she wanted to power wash it. I set it up and warned her, as it says in the instructions, to “treat the nozzle like a loaded gun” and, for the next hour, she power washed everything in sight. Deck, stairs, chairs, tables, carpets – you name it. I stayed way out of her way.

sun sep 4

I fit and welded the last 2 square panels on the fan hood. It is a work of Art!!

I checked valve clearances. All are about as they were last march. (which proves I was barking up the wrong tree yet again) I changed all 8 to next smaller shim to make them ‘even better’. I cleaned the idle jets. A pressure test on just 1 cylinder seemed to show that the valves DO shut off (and should shut off even better with new clearances). So this would point to rings. If the rings are the problem, then why did all 4 of them go bad at once? And why are they all four equally bad? The only commonality I can think of is oil. Is the oil so dirty that the piston rings are sticking? Just thinking out loud here…

mon sep 5

Labor day, and we labored all day. Manual labor.

Mary wanted to torch the burn pile, and she got us a burn permit and notified the sheriff’s department that we were going to burn today, and not to be alarmed. “OK,” they said.

So I put some diesel on the pile and torched it, and that was that.

Not quite.

We moved the thorny piles of rugosa from the hillside garden and burned them.

We took all the piles of brush from locating the south property line and burned them.

We took all the apple tree prunings and burned them.

We cut down a big, dying, leaning tree between Chuck and the barn. We cut it up and kept the good parts and burned the rest.

We cut down 2 trees that were growing tall under the power line and burned them.

We trimmed branches from the pine trees by the road because they were hitting the snow plow trucks, and we burned them.

Mary wanted to cut a tree in the lawn because she hates mowing around it, but I told her to give it a wider berth and mow less lawn.

After all that, we were pretty burned out.

Say what you want, but manual labor gives off a certain satisfaction.

It started as an 8′ high pile, then a 20′ tall inferno, then a 2′ high pile of glowing coals and, by the morning, it was a hot spot on the ground.

tue sep 6

You know those rare clinical trials where the result is so obvious, so early, that it’s un-ethical to keep doing the trial? That’s what happened with the motorcycle today. Leakdown tests of 2 cylinders on the motorcycle were so bad that I didn’t even bother walking around the bike to test the other 2 cylinders, much less try to start it. Face it: the valves are the problem. So I stripped down the head, and I’m going to try to get it right this time.

fri sep 9

To get a decent price, we pre-buy our propane every year, and they give you a choice between a decent price that’s fixed for the season or one that starts off lower, but varies over the winter, based on the spot market, and you take your chances. The idea is that, if the winter is harsh, demand rises, and so prices rise. By choosing the fixed rate, you’re basically gambling that it’s going to be a cold winter and the spot price for mid-season refills is going to rise. We were talking about this and neither one of us could come up with a compelling reason to choose one plan or the other. Until Mary mentioned that the Old Farmer’s Almanac is predicting a harsh winter this year. So we went for the fixed price.

So much for science.

I re-built the valve train on the motorcycle. Again.

Took it apart, cleaned the parts, ground the valves, put it together, adjusted the timing, adjusted the shims, and measured the clearances. This took me about a month the first time I did it, and it took me about 8 hours this time. The main thing I did differently this time was to grind the contact faces of the intake valves flat, because they’d developed an indentation that made it hard to mate with the valve seats. But what really concerns me is: why did they get so gunked up so quickly in the first place? I need to figure that out and fix it, because I don’t want to have to grind the valves every year.

I also overhauled the rear brakes, which were metal-on-metal. No wonder they squeak!

Yesterday, I headed next door with my tool box and no idea what I was going to do when I got there. I’m at one of those points where: I can’t do A until I do B, and I can’t do B until … and the list was circular. In the end, I decided that getting the bathroom underlayment done would open up the floodgates. So I bought some HardieBacker, ruined a couple of saw blades, and got a good start on it.

sat sep 10

Go big or go home. That’s Mary’s philosophy on tomatoes.

Last spring, she planted 27 tomato plants, plus the volunteers she didn’t throw out.

Last summer, they all did pretty good. Lots of greenery and tons of fruit.

Last month, tomato blight hit the garden. The greenery got yellow and the fruit got soft.

Last week, we picked all the tomatoes and spread them out on the floor of the cellar, where they “wouldn’t rot so fast.”

Last night, we cut up the best of the bad ones and made tomato sauce.

This morning, we cut up the rest of them. I was elbows deep in rotten tomatoes, paring off the bad parts. We ended up with 2 big bowls of good stuff and 2 big bowls of slime.

It puts the Great Irish potato famine into perspective.

mon sep 12

It’s just a little thing, but the brakes on the motorcycle are missing 3 of the little rubber hats that cover the brake fluid bleeder drains, so I went to the local car repair place, where they change out brakes for a living, and they gave me a handful of them. Free. Thanks, guys!

tue sep 13

I hate to bore you, dear reader, with details beyond your capacity to comprehend, but try to follow:

I decided to check the points. They’re supposed to be .018, but they were at .008. Way off!! And you can actually, visually see the places where they’re worn out.

It seems that everyone but me knew that when your idle’s bad, and your vacuum’s low, you should look at your points. First thing. Because bad points cause bad vacuum, and bad vacuum causes bad idle. And now, I know it, too.

If we do the numbers, a pair of points seems to last about 2000 miles, and they cost me $50 bucks, or 2.5 cents/mile. Not even including gas: Just for points! That can’t be right. Either I’m doing something wrong, or this motorcycle is a piece of shit.

Next door, the upstairs and downstairs heating zones look really good, and so do the hot and cold water and the PVC drainage pipes. The boiler is too complicated for me, though, so I need a plumber, and I need one fast.

Who you gonna call?

The plumber who put in the plumbing in our place?

The plumber who fixed our hot water?

Or the plumber who is second cousin to the guy who owns the rusty motorcycle?

fri sep 16

In a way, it’s a good thing that the motorcycle is busted, because it gives me more time to work next door. I’m starting to see the light at the end of the tunnel, and focusing on all the details that have to happen before I can sheetrock. The vents for PVC drainage, for example, are a big job, and they’ve got to be routed through some nasty turns en route to the attic.

Combine a 9A motor with a 450 rpm drive and a 5″ hole saw in a tight space where there’s no room for a stabilizing handle, and it kicks like a mule. I have the bruises to prove it.

Charon and Marshall were so pleased with the grab bars I installed near their toilets that they had me install some stair railings outside.

tue sep 20

The motorcycle is fixed. I got the new points in the mail and although, for the life of me, I can’t seem to measure exactly where the wear is on the old ones, I swapped them out, and now it runs like a watch.

It almost didn’t happen, though: The service manual has a table in it that says:

Spark plug gap: .028″

Point gap: .018″

and I went thru the whole procedure with a .028″ feeler gage before I figured out why it still didn’t work. Idiot.

I remember, when I was a kid, we insulated the attic at Wendy Lane, and we itched and coughed for days afterward: Fiberglass and attics are a gruesome combination. To finish the PVC venting in the green house attic, I had to crawl over 2 layers of batts, dragging tools and supplies thru tight spaces, and cut and fit 8 tees and elbows, and then re-arrange the batts to cover them back up as I backed back out. I was coughing, itching and soaked with sweat when I got done, but I got it done. What a fucking job!!

And in the middle of it, Mary showed up to tell me the lawn mower had given out. Just stopped in its tracks! I put in a new gas filter I just happened to have, and it started right back up.

Then I went right back up into the attic.

thu sep 22

Since today was going to be the last nice day for a few days, and

Since I haven’t taken a motorcycle ride all month, and

Since the bike is now more fully refurbished than it’s ever been in its life and ought to be running like a swiss watch, I decided to take a motorcycle ride today.

But where to go? Well, there’s a lot of apples on the trees, and they’re about to be ready for picking, and all year long, I’ve been telling myself that, before apple season, I was going to build me a cider press, so I could sample and test the juices from the different trees. And here it’s almost apple season, and I still don’t have a press! So I made a set of slats for a miniature press. And then I got to thinking: once I’ve pressed some apples, I’m going to have to keep the juice from spoiling for a few days. So I googled “wine making supplies”, and there’s a place in Plainfield where I can get some potassium sorbate.

So I took the motorcycle to Plainfied, 50 miles away, and I didn’t take any tools with me at all. How’s that for confidence? It was a beautiful day, a nice ride, and the motorcycle ran like a swiss watch.

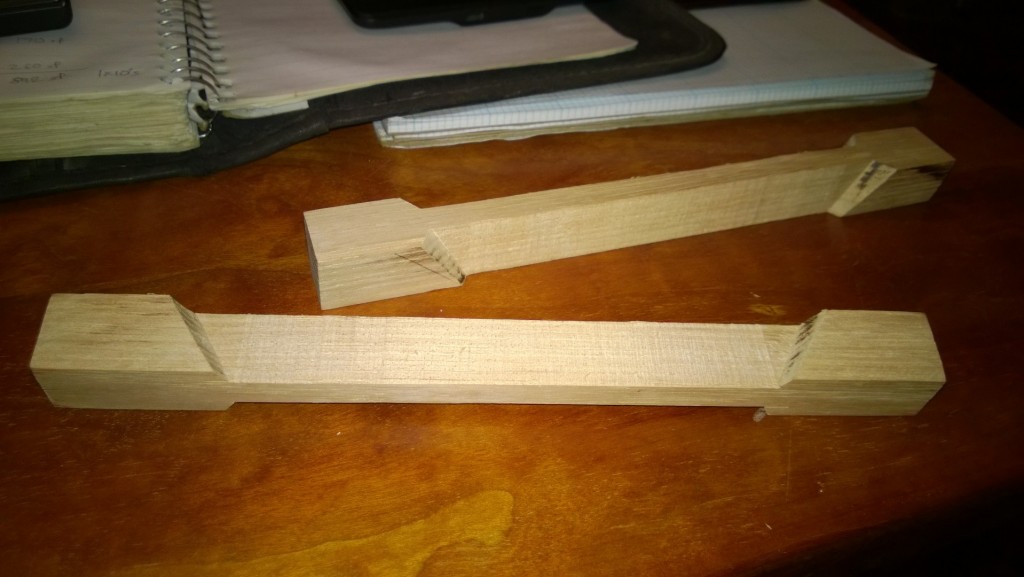

I’m not saying this is the best way to make an apple cider press but, for sample batches I wanted a mini-press, and these slats did the job. With 14 facets per slat, though, they were a bitch to sand.

I took up the painted plywood portion of the living room floor next door and, under it was – surprise! – another floor. Genuine fake wood parquet linoleum.

Taste takes a vacation.

sun sep 25

Suri’s birthday is tomorrow (she’s 9), so a birthday party was in order. But first, we went apple picking at Hackett’s in South Hero. I’ve been in VT for 36 years now and I’ve only been Picking once and it was kind of a bust, so I wasn’t expecting much excitement. But with my new-found interest in cider making, I thought I might learn something and tagged along. It was a beautiful day, and half the population seemed to be there, and we rode in the back of a trailer down to the trees and picked about a bushel of apples. The trees were mostly 32 years old and, in spite of being loaded with fruit, they said it was not a very good year. Mary struck up a conversation with the owner, but I didn’t realize who he was, or I’d have pumped him for information. Most of the apples were pretty common commercial varieties (Macintosh, Cortland, Macoun, etc) and were good for eating, but I thought they were kind of bland, compared to the mouth-puckering fruits our own trees produce. I ate one of every variety and got the shits a few hours later, but as a learning experience, it was worth every fart. I could see that the grass was mowed even under the trees, they fence against pests, they prune carefully, tag each tree, protect the rootstocks from mice, and generally run an attractive farm. We had 2 kinds of cider donuts and an ice cream cone and then went to Maggie’s for tacos, cake, and more ice cream. (Tomorrow, I’m supposed to have (routine) ‘fasting’ blood work done, and Mary’s afraid all that sugar and fat is going to skew my results.)

It was a fun day, but I didn’t get a damned thing done.

We picked 4 kinds of apples, and I wanted to keep them separate so I could see how the juices differ. But since most red apples are hard to tell apart and I only bought 1 bag, I tied off the ends of my sleeves and filled them with apples.

And got some strange looks.

wed sep 28

A plumbing convergence is happening. I’ve got 2 quotes for doing the boiler, and the Blue Flame guy came by and blessed the site for a tank. It seems the only thing that isn’t ready is me! It’s taking me forever to tie up all the loose ends in the plumbing, and I think I know why: I’m just not a very good plumber. It seems that every time I try to do something, I need to go to the store first, and that slows me waaay down. Even so, I’ve got all 13 heat registers sweated into place and my to-do list is telling me there is “less piping in the pipline.”

Each baseboard heat register came in a cardboard box and I was having a hard time opening the boxes, so I pulled a chisel out of my pocket and used it to wrestle with the boxes. Next thing you know, instead of having a chisel in my hand, I had a chisel IN my hand!! I had a physical exam scheduled for the next day and the doctor looked at me, looked at my records, and gave me a tetanus booster.

I figured out how I want the frame for the kitchen fan grille to work, but I can’t quite figure out how to make it. I bought some 16-gauge sheet metal and promptly found that it’s too thin for stick welding, so I decided this would be a good excuse to try out my new MIG welder. But MIG welding is not like stick welding at all, and I suck at it every bit as bad as I sucked at stick welding when I made the gutters. So I’ve been practicing on scrap, because I’m only going to get one chance to fuck this up.

The fan intake grille is a pyramidal affair, and I need to weld the seams without blowing a hole through it. I’m trying to make my mistakes on scraps.

I pressed some apple juice with my new mini-press. Twelve buttercup apples, from Apple Picking with the girls on sunday, gave me 660 ml of juice, and the whole process worked pretty good, for a first try.

thu sep 29

I had a complete physical exam, and a clean bill of health. Drink to that!

Mary’s gone to NY to bring Celia up for the weekend. My job: Make meatloaf for dinner.

I took a break from practicing my MIG welding to make meatloaf.

With wire-feed welding, the trick is to get the arc started and to immediately begin a smooth move.

It turns out this is the exact same problem you have when writing with ketchup!

I pressed 3 more kinds of apples and I’m getting the hang of it:

A brimming bowl of apples, when fed thru the grater, exactly fills the Cuisinart.

A Cuisinart full of ground-up apples exactly fills the mini-press.

A full mini-press yields about 750 ml of juice and 750g of pulp.

I got a ladder and picked apples from 3 more trees, so I’m ready to try it with our wild apples.

fri sep 30

I got right to work processing apples this morning, and I started with the crabapples. The nice thing about crabapples is that they’re small enough that you don’t have to cut them up to fit them into the food processor, and it saves a step, because – let me tell you – there are a lot of fucking steps involved in getting the juice out of an apple. You gotta pick, store, wash, chop, grind, press, and bottle them, and then you have to wash everything off before you start on the next kind of apple.

So far, making apple cider is making maple syrup look easy.

I rode up to CMF with some sheet metal and asked Dave to shear it into pieces I could practice on. He was really good about it and explained to me the way he would go about doing the weld on my hood. He was full of good advice, but I missed about half of it due to the din and clanging behind me. Thanks, Dave.

I’ll be using Dad’s nibbler tool for some of the shaping I’ve still got to do on the hood.

Check out the brand name.

Comparing apples to apples.

Yes, they all taste like apple juice, but they’re all different, and English seems to have no terminology to describe how tannins feel in your mouth.

It took them awhile, but the pumpkins finally took off.

The little one is about 10″ across. No blue ribbon this year!