mon jan 1

A lot of the paint on the Kawasaki was peeling when I got it, and it looked like the peeling parts were from an owner paint job, rather than a factory powder coat. Last month, I showed you some parts I’d stripped and re-finished: These parts (a valve cover and some brake calipers) get pretty hot, so I was careful to pick a high temperature paint. One place had ‘caliper paint.’ Another had ‘engine block paint’. Both rated for 500º, and ‘impervious to automotive fluids.’ So I bought a can, sprayed the parts, and they looked great.

Today, I re-assembled the brake calipers, only to find that the new paint dissolves in brake fluid! It’s disappointing, but as long as the brakes work perfectly, I don’t much care what they look like.

sat jan 6

It’s 13 days after Christmas, and we never got around to eating one last piece of leftover prime rib. By coincidence, we’re also out of cat food, so for 3 meals, BZ was one happy cat.

mon jan 8

The Kawasaki and the Suzuki are very similar bikes, and one thing that hasn’t changed is the stupid mistakes I make. The other day, I began re-assembling the valve train, starting with the valve stem seals. Whoops! The spring washer needs to go on before the seal, and taking the seals back off usually means destroying them. It was looking like $40 bucks down the drain until I made the world’s ugliest (only?) valve seal removal tool.

A narrow escape.

wed jan 10

And 2 days later, I was removing the pistons when one of the ‘circlips’ popped off the pliers, fell into the crankcase, and landed ‘buttered side down’ in a remote part of the oil pan. I’d been wondering whether it was worth it to replace the oil pan gasket, and suddenly, the answer was Yes.

The Woodstock Farmer’s Market threw Lisa a ‘retirement’ party, complete with an open bar, a ‘shot machine’ and, since Lisa is a big cheese in the cheese world, some really fine cheese platters. Since the place was noisy as hell and I didn’t know a soul, I staked out a spot by one of the platters, munched away, and watched the crowd.

I watched as a certain sister-in-law, who is normally quite dignified, blocked the view with her body, looked both ways, heaped a hanky with a generous pile of cheese slices, and slipped it into her purse.

sun jan 21

Bill and Lisa, the couple across the street, are having a rough winter. They had a burst pipe, a septic backup, health issues, and some sick animals. I hear about it from Mary, and Mary hears about it from Lisa, and when a recent news flash was that the old goat was sick, it took me awhile to realize she was referring to a pet goat, and not to Bill.

tue jan 23

It’s been a long haul for Mary. Eleven weeks after her 2nd surgery, she’s finally allowed to start putting some weight on her leg. Not much, but you gotta start somewhere.

wed jan 24

One thing I’m not good at is maintaining a clean workspace.

I was ready to put the pistons back in the Kawasaki, and everyone says that assembling an engine calls for cleanliness. I wanted to get it right, so I let the dust settle overnight and then wiped down my benches with WD-40, threw out all my dirty paper towels, and laid out my tools and parts. Unlike the Suzuki, the KZ piston pins are a press fit, and I heated up the pistons with a hair dryer to ease the insertion. With a piping hot piston in one hand and a greased pin in the other, I backed into position – and knocked over a bucket of penetrating oil onto the floor. Shittagoddam! Next thing you know, I was on my hands and knees, mopping up the puddle with a gritty wad of discarded paper, and ‘clean’ was a thing of the past.

In the end, I got the job done, but I decided to spend the rest of the day doing something I’m good at: Making dirt.

sun jan 28

After making a lot of required improvements to Mary’s new building, it was time to move her business. The first time she moved (from Frank’s shop in NY to ‘the plant’ in Morrisville) all it took was 2 trips in a rented truck. The second time, from ‘the Plant’ to ‘the Mill’, it took several truck loads and many trips. This 3rd time, from ‘the Mill’ to ‘the Shop,’ it took a rented semi and a dozen round trips with a pair of 16′ trailers. Plus a few loads with my puny little truck. I pitched in for two days and, although I can keep up with men half my age, I was plenty sore when I woke up this morning. Her huge new space is not looking so huge right now, with pallets and piles everywhere, and we all hope that, as part of the un-packing process, she’ll throw half of it out.

Devin and John moving the original kettle in which Bob used to cook tung oil back in the early days.

Over an open flame!

BZ the cat usually ‘goes out’ after breakfast, and he’s usually only too happy to come back in after he’s done his business. This morning, when I went to let him in, he was on high alert, with his eyes glued to the ceiling. I looked up, and he’d chased a squirrel up the wall. It was cornered, and not happy about it. I settled into a deck chair – in bare feet and a tee shirt in 35 degree weather – and watched the drama play out. Long story short: the squirrel lived to tell about it.

mon jan 29

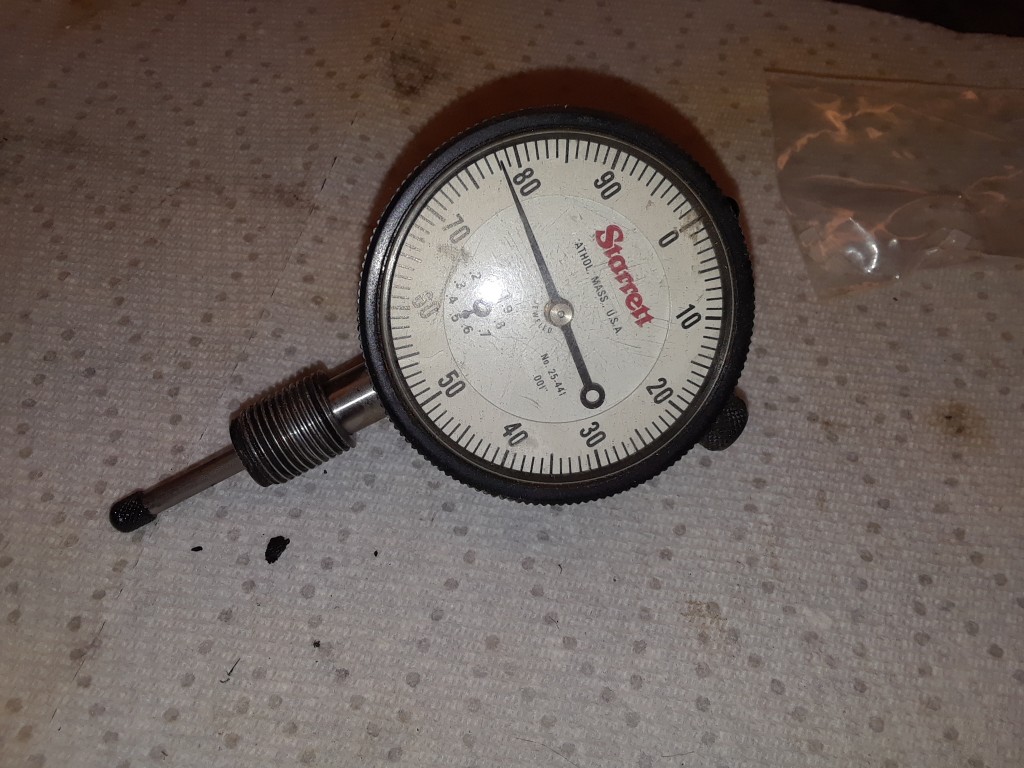

Now that I’ve got the Kawasaki’s pistons, cylinder block, and cylinder head back together, it’s time to install the cam shafts. This is usually ‘easy’ and step 1 is: “turn the crankshaft to the Top-Dead-Center timing mark.” The problem is that the previous owner replaced the points with electronic ignition, and there is no timing mark. So how do I set the phase of the camshafts? A popular solution on google is to stick a dowel rod into a spark plug hole and look for the high water mark of the piston’s travel. That’s a little too primitive for me, though, because of the scary consequences of getting it wrong.

I decided to try to mount a dial gauge in a spark plug hole, but the threads are an unusual M14x1.25, which I can’t turn on my lathe. In the end, I cut a spark plug in half and reamed it to fit my dial. It was a bitch, but it worked perfectly.

Spark plugs are indestructible.

Hardened steel filled with durable ceramic, designed to withstand thousands of explosions per second at point blank range.

Brute force helped, but dumb luck ruled the day: My plug has metric threads, with an imperial bore that just happens to exactly fit my dial.

wed jan 31

The hardest thing about c3pr’s mechanical design has turned out to be specifying exactly which motors and bearings and connectors to use. Finding a source who will sell you exactly 1 unit – spec sheets and all – is harder than you might think, and prices can be scary.

The next hardest thing is restraining myself to doing my best work. Concentricity, perfectly right angles, and fitment are not my strong points, so getting it right has really slowed me down. It turns out that 3.5″ I.D. aluminum tube is pretty awkward to work with on my machines, so most of this month’s machining involved jigs for work-holding.

Not a recod-breaking month, but good progress.