wed feb 7

I gave Mary an Amazon Echo for Christmas and it took awhile for her to get around to setting it up. It works as advertised – most of the time – and is good for queries with well-defined answers. Whenever it hears ‘Alexa,’ it begins to pay attention, and when we talk about Alexa (as opposed to to her), she hears her name, can’t quite parse the context, and pipes up with “I’m not sure” or “Sorry, I don’t know how to do that.”

After a couple of irrelevant interruptions, I finally said “Alexa, shut the fuck up” and her LEDs lit up, shut down, and she mostly ignored us for the rest of the evening.

After a successful query, Mary tends to say “Thank you, Alexa” and, after hearing this a few times, Alexa learned to respond with “You’re welcome.”

Lisa’s birthday was last week and she got … news that her tumors are back. Since ours is the only warm house and travel with a wheelchair is problematic, we gathered here for lunch.

After a certain age, you only get a couple of candles on your cake, no matter how old you are.

sun feb 11

If you haven’t noticed, I mostly blog about my mistakes.

My blunders. My do-overs. My boo boos. My fuck-ups.

And if I haven’t been blogging much lately, it’s partly because I don’t seem to be making so many mistakes, and who wants to hear about things that go smoothly?

I mused, a few years ago in this space, about the nature of piles.

When we demolished Mary’s barn about 10 years ago, we de-nailed most of the wood (“barn boards”) and then stacked and stickered them in (what was left of) the barn. Naturally, we stacked the best boards first, followed by the ones which were ‘a little rotten, but not too bad.’ At that point, it was just as easy to give ‘the best of the rest’ the benefit of the doubt and add them to the top of the pile instead of hauling them to the burn pile. The bottom line is that, in the resulting pile, the best boards were on the bottom.

Fast forward to 2018, and I’m trying to make barn board doors for the green house, and the ones I need are … on the bottom of the pile.

Turning the first batch of barn boards into ship-lap doors.

By now, I’ve got over 150 boards in play (plus the rejects), and my enormous shop is feeling pretty small.

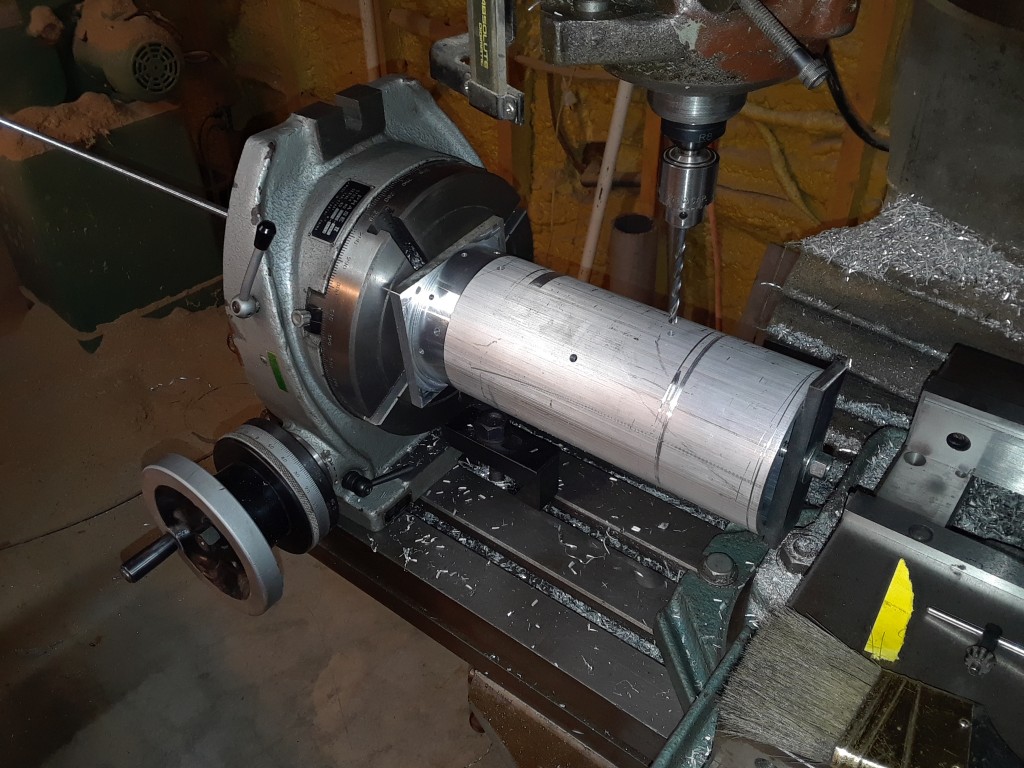

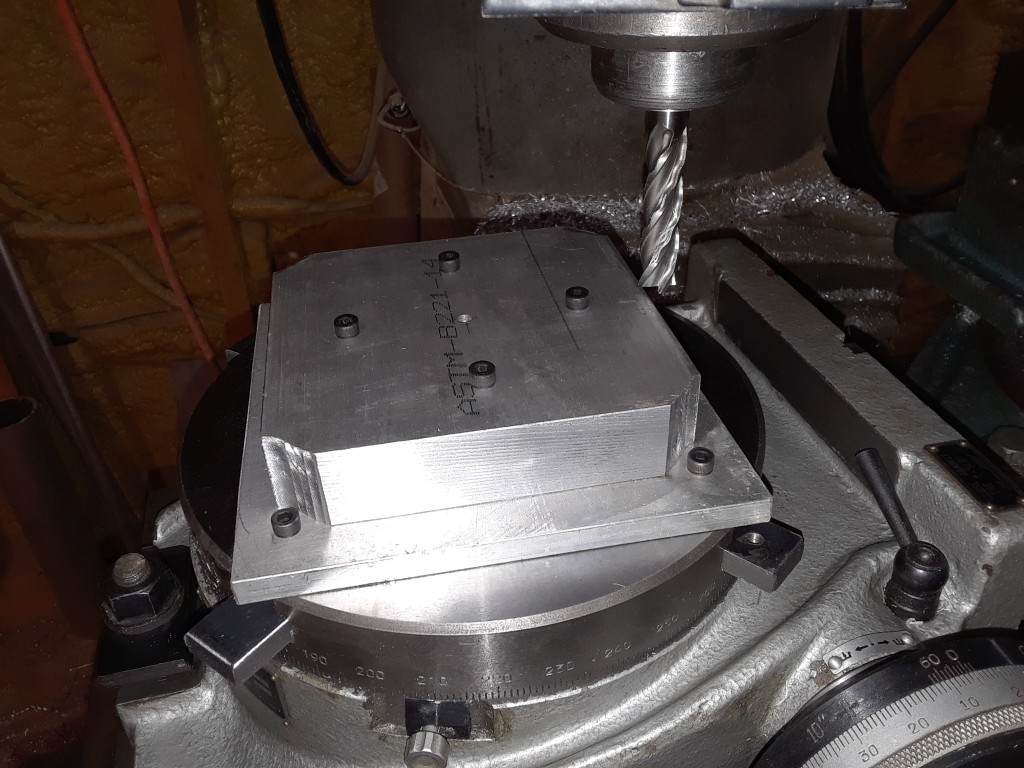

Part by part, I’m making good progress on c3pr. I’ve been dabbling in metal work for just over 20 years now (!!) and it seems that every mistake I ever made and every tool and attachment I ever acquired are coming in handy. Here are some photos:

Drilling radial holes for all the goodies that mount inside the upper arm.

Another clever work-holding solution.

… and ended up looking like this.

In between, there was a lot of careful re-clamping for a distortion-free thin shell.

Note the accompanying CAD drawing.

mon feb 12

I usually sleep-walk through my morning routine of feeding the cat and making coffee, and it usually comes out fine. This morning, I was making Mary’s coffee, which starts out with milk and a spoonful of sugar, when I grabbed the wrong jar and put a spoonful of dry cat food in her cup. I dumped it out and started fresh, but – just in case – double-checked to make sure I hadn’t given the cat coffee. Nobody got hurt.

mon feb 19

I used to use plain old phillips screws in all my projects, but started using trim-head a few years ago because … they look better. Next door, I used them in the floors, the jambs, the trim, and elsewhere, and whenever I ran out, I’d just buy another box. When my lumber yard ran out, I started buying at another lumber yard. Last month, I started making barn-board doors, and … I ran out of screws and so did my back-up lumber yard! I checked every yard in the county and came up with less than a door’s worth of trim screws. I was screwed!!

Eventually, I found the Mother Lode in a store in Stowe, bought several boxes, and haven’t run out … Yet.

wed feb 21

It’s two days later, and I’m out of screws again.

thu feb 22

The shop is a mess. I turned a gi-normous pile of barn boards into a large pile of doors, and now I have piles and piles of offcuts, boxes and boxes of kindling, and a thin layer of sawdust covering everything. Three separate air-handling systems work wonders, but I still have to let the dust settle overnight before I switch gears from woodwork to carburetors.

sat feb 24

Maggie and the girls came over for ‘taco night’ and, for my first taco, I helped myself to some ground beef, topped it with goodies, and took a big bite. It tasted “off” and had the texture of grape nuts, but I kept it to myself. Only later did I learn that Sophia’s friend was vegetarian, and the mystery meat was soy. Thank god for margaritas.

mon feb 26

Want to get rich? Invest in cardboard boxes.

The internet economy is kicking in, and I am doing my share. It seems that all my projects are stalled right now because I’m waiting for packages to be delivered.

Motorcycle? Waiting for jets, O-rings, gaskets, bearings.

C3pr? Waiting for servo, gearbox, connectors, power supply, and metal stock.

Green house? Waiting for hinges, knobs, and sliders.

No less than 10 deliveries are pending, and I’m chomping at the bit.

It used to be that Home Depot and Radio Shack would have most of the stuff I need, and if they didn’t, I’d buy whatever they had that was ‘close enough.’ Nowadays, though, I don’t buy it unless it’s exactly what I want, but the wait is killing me.

So far, I can’t imagine buying groceries online, but last week, Mary ordered a bunch of gluten-free wide noodles that she can’t find in the stores. Can underwear be far behind?

tue feb 27

My laptop is vexed. It says the hard drive is full, but when I add up, folder-by folder, how much space I’m using, it’s less than half the capacity of the drive. None of the basic suggestions I tried from google helped.

So I started working through the 2nd tier of suggestions, for people who just don’t give up. Most of them start out with “download <this or that> 3rd party disk utility and run it,” but since the disk is full, you can’t download anything! So I moved some photos to a thumb drive to free some space, did a download, and followed the directions, and it came up with 80 Gig of “system junk files” — stuff that’s left over when Windows fails to clean up after itself.

So I’m back in business, but still steaming over the wasted effort.

The Kawasaki re-build is in the home stretch.

I’ve got the cylinders honed, new rings, the head re-built, the valve shims adjusted, the cams timed, and the oil pan replaced.

I found and fixed a broken bolt in the clutch linkage, fixed a seized pivot on the rear brake, and I’m replacing the swing-arm bearings.

I was re-assembling the carburetors and couldn’t figure out how the pilot jets worked until I realized that not one, not two, but all 4 of them have blocked orifices, even after an overnight soak in carb cleaner.

When Creemee season rolls around, I’ll be ready!

wed feb 28

C3pr is burning a hole in my pocket.

Writing software for a couple years may have been a waste of time, but it was free. Building hardware, on the other hand, costs money.

My immediate plan is to build 3 (of 5) joints (the hand, the wrist, and the shoulder) and see if I can get them working. The hand and wrist are activated by small motors, without a lot of inertia. I expect to screw them up, but I know I can make them work.

The shoulder is the outermost joint where there’s a ton of torque involved, and it won’t surprise me if the whole assembly decides to dance/rattle across the room. I just plain don’t know what problems to expect, so stay tuned.

If the shoulder is going to work, it’s going to need a first class motor and, according to my calculations, this monster should do the job.

The controller is a computer unto itself and, in a sign of things to come, I spent my first hour with it trying to figure out how to connect (and disconnect) a wire to the gray terminal block on the left.

The answer: poke it with a screwdriver and jam the wire in hard. Just like the motorcycle.

One Response to February 2018